-

Email

corporate@cloudzeninnovations.com -

Phone

+(02) - 094 980 547 -

Address

Hennebergerstrasse 35, 90475 Nuremberg, Germany

©2025 Cloudzen Innovations | All rights reserved.

Phone

+(02) - 094 980 547Address

Hennebergerstrasse 35, 90475 Nuremberg, Germany©2025 Cloudzen Innovations | All rights reserved.

CloudZen Innovations has partnered with a leading European discrete manufacturing company to modernize their production operations through advanced machine learning and robust data engineering.

The objective: to implement predictive maintenance, enhance production quality, and improve operational efficiency across multiple factories.

The manufacturer had been relying on outdated technology, lacking any predictive analytics capabilities—resulting in unexpected equipment failures and significant financial losses due to unplanned disruptions in production.

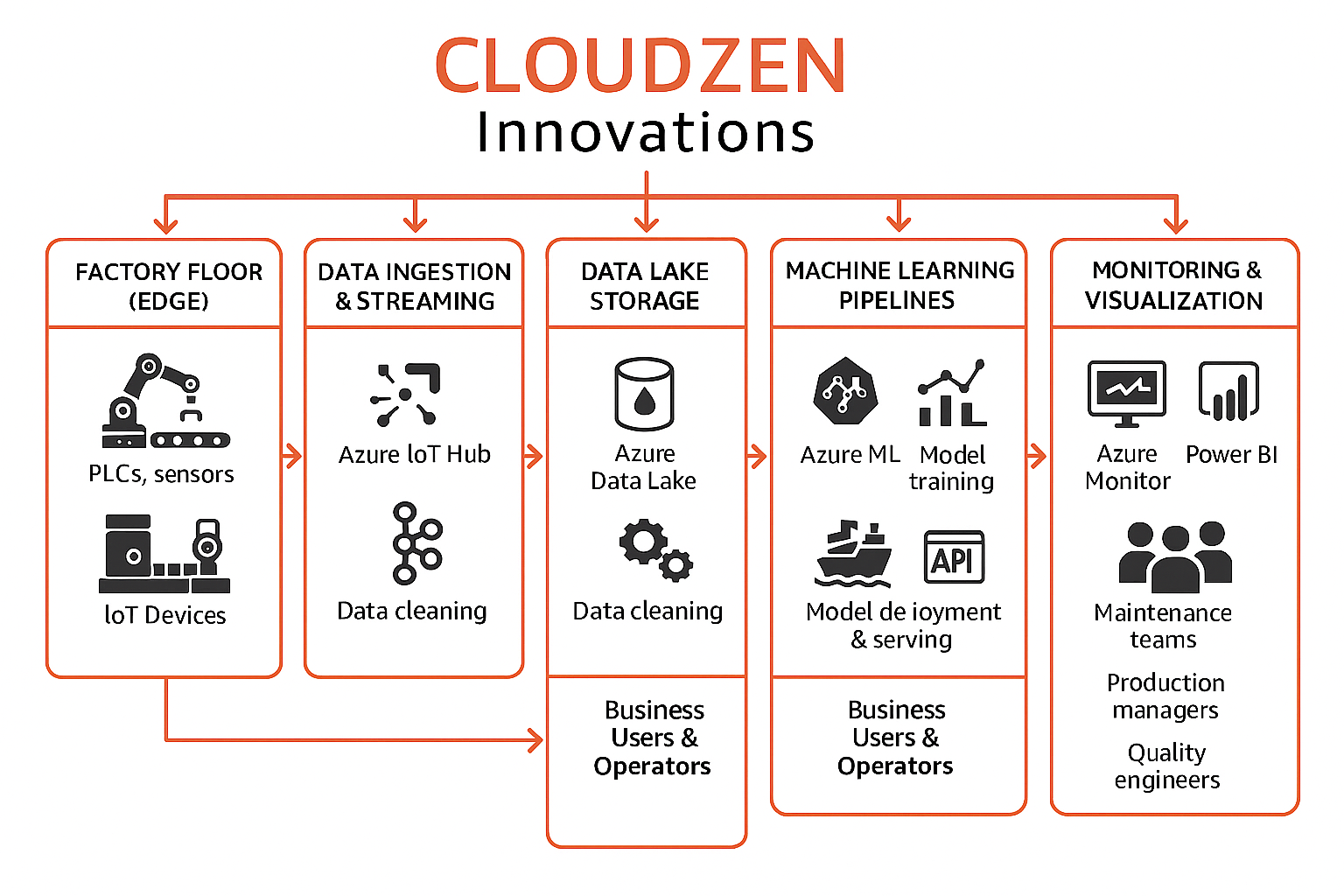

Leveraging its expertise in data engineering, MLOps, and multi-cloud automation, CloudZen designed and deployed an end-to-end solution on a secure, scalable cloud-native architecture.

© 2025 Cloudzen Innovations | All rights reserved